Research News

[Prof. Seung Hwan Ko] Novel laser-thermal mechanism realizes ultra-fast construction of PDMS devices

Author

mina7789

Date

2024-04-12

Views

334

Researchers at Seoul National University in South Korea reported the development of new laser-based polydimethylsiloxane (PDMS) processing mechanism that enables the mask-less direct fabrication of various PDMS structures. This novel technology, named successive laser pyrolysis (SLP), provides an elegant alternative for conventional soft lithography, which is labor-intensive and time-consuming, by utilizing a newly discovered laser-guided successive pyrolysis phenomenon.

To date, the fabrication of various types of PDMS devices heavily relies on soft lithography. The complicated multi-step procedures, necessitating photolithography, however, draws substantial inefficiency to the associated research environments. Especially to the field engineers, the frequent design modification at the early research stage and subsequent repetition of the complex process was a significant burden. To remedy the situation, several researchers focused on the direct laser patterning of PDMS. However, the transparency of PDMS frustrated the attempts based on laser technique. Although UV laser-based ablation of PDMS, which can overcome the transparency of PDMS, was tried, the result has not reached the level of practical use mostly due to the poor surface topographies like burrs, debris, and fractured surfaces. For these reasons, the development of a non-ablative laser technology that enables high-quality PDMS processing has been an old challenge.

The recent paper published in Nature Materials on August 17 introduces the first-ever successful development of non-ablative direct laser machining of PDMS that enables a practical level of processing quality. Firstly, the paper describes the principle of 'laser-guided successive pyrolysis' that resembles the chain reaction; the opaque product of pyrolyzed PDMS (SiC) promotes enhanced laser absorption leading to the initiation of the next pyrolysis. As a result, the PDMS pyrolysis can proceed continuously along the contour of laser scanning without any special modification of PDMS. Based on this process principle, the researchers demonstrated the direct forming of various 2D and 3D PDMS structures starting from a PDMS monolith remarkably in a dramatically reduced processing time.

Professor Seung Hwan Ko, who led the research, said: "This new technique paves a shortcut to bridge a bare idea of PDMS devices in researcher's mind to a tangible device within a significantly reduced process time of less than 30 min in most cases." Compared to the conventional process that takes at least one day, such a reduction in process time, in addition to excellent processing quality, is expected to have a practical impact on researchers in relevant fields. As a next step, the research team are paying special attention to the grafting of this technology toward the development of Organ-on-a-chip.

This work was funded by the Ministry of Science and ICT, South Korea; by Seoul National University (SNU)

To date, the fabrication of various types of PDMS devices heavily relies on soft lithography. The complicated multi-step procedures, necessitating photolithography, however, draws substantial inefficiency to the associated research environments. Especially to the field engineers, the frequent design modification at the early research stage and subsequent repetition of the complex process was a significant burden. To remedy the situation, several researchers focused on the direct laser patterning of PDMS. However, the transparency of PDMS frustrated the attempts based on laser technique. Although UV laser-based ablation of PDMS, which can overcome the transparency of PDMS, was tried, the result has not reached the level of practical use mostly due to the poor surface topographies like burrs, debris, and fractured surfaces. For these reasons, the development of a non-ablative laser technology that enables high-quality PDMS processing has been an old challenge.

The recent paper published in Nature Materials on August 17 introduces the first-ever successful development of non-ablative direct laser machining of PDMS that enables a practical level of processing quality. Firstly, the paper describes the principle of 'laser-guided successive pyrolysis' that resembles the chain reaction; the opaque product of pyrolyzed PDMS (SiC) promotes enhanced laser absorption leading to the initiation of the next pyrolysis. As a result, the PDMS pyrolysis can proceed continuously along the contour of laser scanning without any special modification of PDMS. Based on this process principle, the researchers demonstrated the direct forming of various 2D and 3D PDMS structures starting from a PDMS monolith remarkably in a dramatically reduced processing time.

Professor Seung Hwan Ko, who led the research, said: "This new technique paves a shortcut to bridge a bare idea of PDMS devices in researcher's mind to a tangible device within a significantly reduced process time of less than 30 min in most cases." Compared to the conventional process that takes at least one day, such a reduction in process time, in addition to excellent processing quality, is expected to have a practical impact on researchers in relevant fields. As a next step, the research team are paying special attention to the grafting of this technology toward the development of Organ-on-a-chip.

This work was funded by the Ministry of Science and ICT, South Korea; by Seoul National University (SNU)

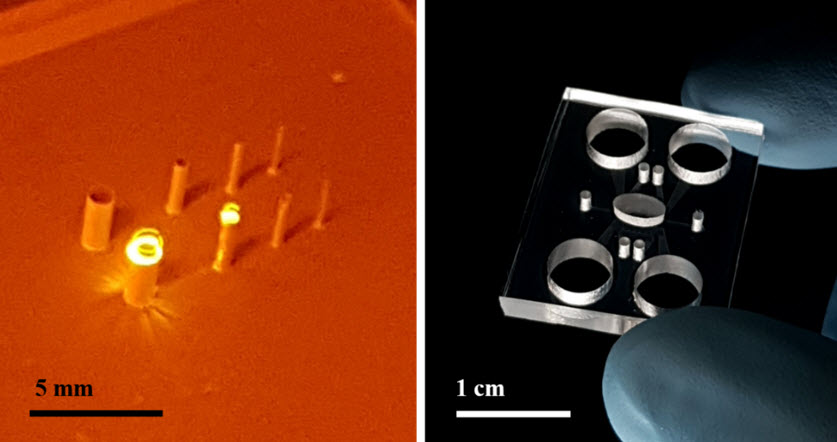

Figure. Featured images of SLP. Left: Digital image of SLP process forming vertical microchannels inside PDMS. Right

Figure. Featured images of SLP. Left: Digital image of SLP process forming vertical microchannels inside PDMS. Right

: Digital image of 'Skin-on-a-chip' device fabricated from a PDMS monolith through SLP process.