Department News

[The Hwankyeong Ilbo] Prof. Byeng Dong Youn [Optimal Smart Factory Forum ⑥] Leading Globalization with Combined Industry 4.0 Te

[Optimal Smart Factory Forum ⑥]

Leading Globalization with Combined Industry 4.0 Technologies <?xml:namespace prefix = "o" ns = "urn:schemas-microsoft-com:office:office" />

"Smart Factory Using Industrial Data Predsict Industrial Info"

OnePredict CEO Byeng Dong Youn Presents ‘Successful Cases of Industrial AI and Global Commercialization’

Prof. Byeng Dong Youn, CEO of OnePredict

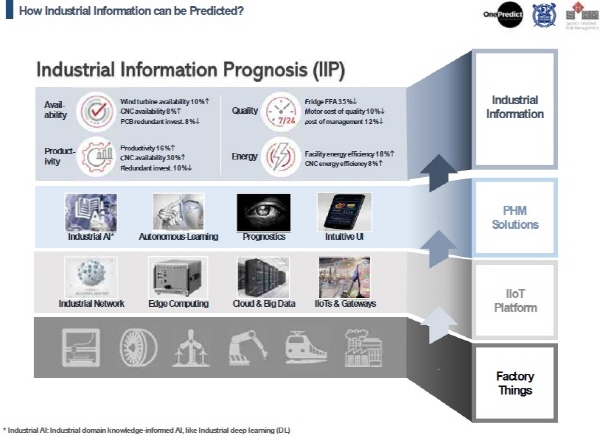

[Seoul National University=The Hwankyeong Ilbo] Bong-woon Kim = AI technology, with dramatic developments in cloud computing and big data, has now become a key element in 4th Industrial Revolution.

OnePredict was founded by its CEO Byeng Dong Youn (SNU Professor) and his students. The company provides prognostics and health management services for engineering equipment.

Prognostics and Health Management is a core technology in Industry 4.0, combining AI, IoT, and big data analysis. Prof. Youn provides solutions for companies around the world.

Industrial data

World’s Best ICT Solutions and Technology Development

As industrial data becomes more important, the technology for understanding and utilizing industrial data is also turning out to be crucial. Industrial Artificial Intelligence deals with industrial data, performing more precise analyses and prognostics. OnePredict approached the market by introducing Industrial AI technology in predicting equipment and component failure in manufacturing.

When factory equipment fails unexpectedly, the company suffers heavy loss since it is forced to stop manufacturing for a long period of time. “By performing prognostics and failure prediction, equipment maintenance can become much easier,” said CEO Youn. “Sensors and SW provide real-time status analysis. Both productivity and competitiveness can be greatly increased.”

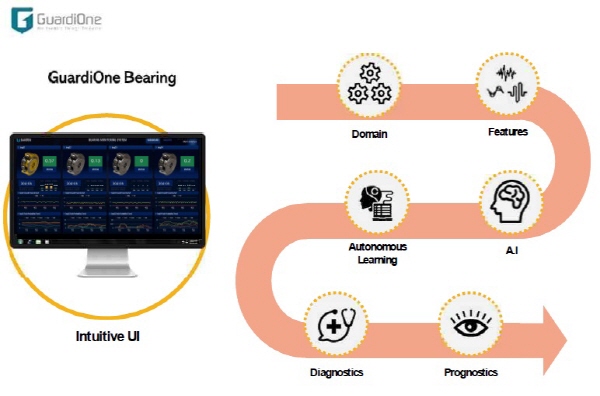

In fact, OnePredict provided solutions for ‘Schaeffler,’ world’s top-level German manufacturer of bearing. Constant monitoring of equipment status enables the company to examine any signs of failure beforehand.

Solutions for 'Schaeffler' solutions

Schaeffler applied OnePredict’s solutions to their own products, and signed a purchasing agreement after seeing the results.

“For example, a wind turbine has to be shut down for as long as 6 months if failure occurs in its main bearing or gearbox,” explained Prof. Youn. “You place an order for the component, which costs more than 100 million won, then they have to manufacture it and ship it. Then you have to go through stabilizing. The whole process can take 2 to 6 months.”

“Our technology predicts failure 2-3 months before it happens, providing the company plenty of time to acquire the necessary components beforehand. This can dramatically shorten the stoppage time of the generator,” he continued. Adopting OnePredict’s technology for smart factories will enable easier management and maintenance and allow fast responses to various risks.

Bong-woon Kim bongwn@hkbs.co.kr

Link to article http://www.hkbs.co.kr/news/articleView.html?idxno=503524