Department News

[SNU Engineering] Prof. Suk Won Cha on Hydrogen Fuel Cell Vehicles

Author

관리자

Date

2021-07-27

Views

1013

SNU Engineering Research News > New Technology Trends

Prof. Suk Won Cha

SNU Dept. of Mechanical Engineering

Introducing Hydrogen Fuel Cell Vehicles

Hydrogen fuel cell vehicles, or fuel cell electric vehicles, are a type of eco-friendly cars powered by hydrogen, emittingly water as exhaust. So they are perfect for downtowns with heavy traffic and driving between cities.

The world’s first hydrogen fuel cell vehicle is the Chevrolet Electrovan manufacturerd by General Motors in 1966. It used proton-exchange membrane fuel cell (PEMFC), could run for 120 miles, and had the top speed of 70mph. However, due to technological constraints, it had to carry both hydrogen and oxygen tanks, with the bulky fuel cell system taking up most of the space in the car. Only up to two people could ride it.

Chevrolet Electrovan, world’s first fuel cell electric vehicle, made by GM. (GM website)

Due to massive production costs, theyly builte car. But the PEMFC went under development by General Electric, who participated in the Gemini and Apollo projects with NASA. In the 1980s, the Los Alamos National Lab developed the electrode technology which dramatically reduced the use of platinum catalyst, greatly improving economic feasibility. In turn, various companies began to develop hydrogen fuel cell vehicles using PEMFCs.

Ballard, a Canadian company founded in 1979, has much experience in the development of fuel cells. In 1993, it showcased world’s first fuel cell bus, later developing hydrogen fuel cell cars with Honda and Chrysler. Hyundai Motors also began to develop their own in the 2000s, cooperating with American company UTC Fuel Cell.

These companies participated in the California Fuel Cell Partnership. The headquarters were built in Sacramento in 2000, expanding hydrogen charging stations across the state and accumulating driving data of fuel cell electric cars. Hyundai Motors, Toyota, and Honda developed their own unique hydrogen fuel cell technology via continuous research and development. Currently, they are leading automobile manufacturers in the world equipped with mass production systems.

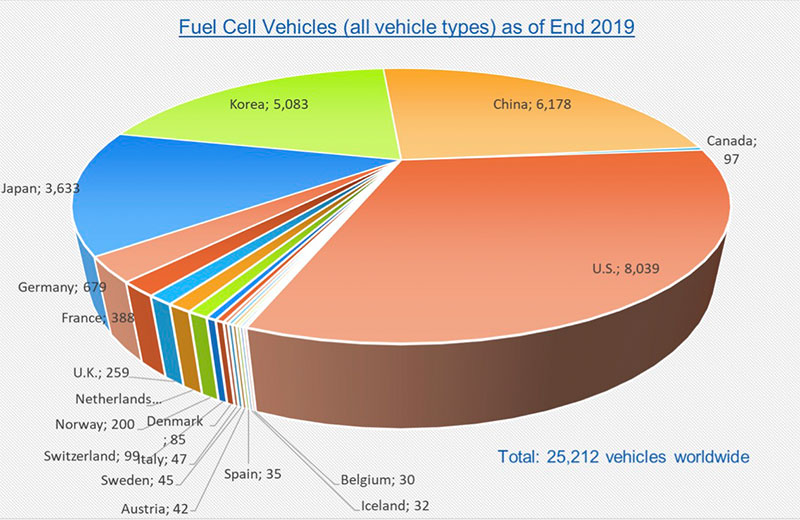

Global distribution of fuel cell vehicles as of end of 2019 (2020 IEA)

As of end of 2019, there are more than 25,000 fuel cell vehicles distributed across the globe. The distribution rate shows rapid increase from 80% in 2018 to 95% in 2019. Asia takes up more than half of global distribution, followed by US then Europe. Among the fuel cell vehicles in use, 75% are automobiles with commercial vehicles like buses and trucks taking up the rest, which are mostly used in China. China is choosing to focus hydrogen technology as part of their national development strategy. Since their technology is less developed compared to Korea and Japan, China is using fuel cells in commercial vehicles, which are relatively easier to develop. They also have constructed Ballard’s large-scale production factory for fuel cells in Shanghai, encouraging the supply of commercial vehicles and improving operational technology.

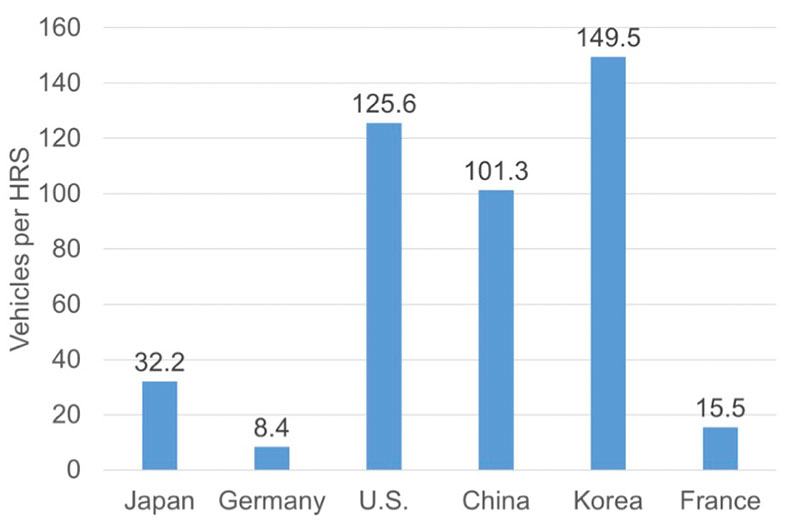

Percentage of vehicles per HRS (Hydrogen Refueling Station) around the world (2020 IEA)

In addition to vehicles, distribution of hydrogen refueling stations is also a critical factor. Unfortunately, Korea has the highest percentage of vehicles per HRS in the world, showing a significant lack of fueling stations. US and China also lack stations, but are quickly increasing their number. Japan and Germany boast excellent distribution rates as strong leaders in hydrogen technology.

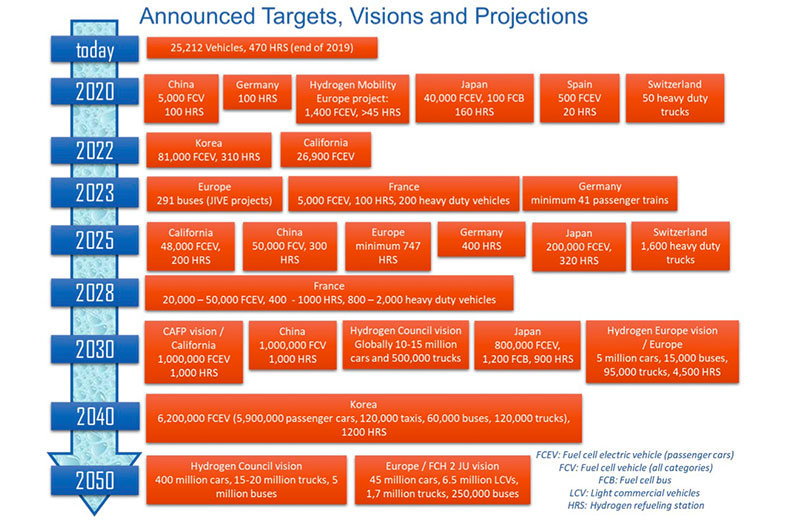

Projections for fuel cell electric vehicles and hydrogen refueling stations around the world (2020 IEA)

US, China, Japan, and EU all have announced aggressive distribution plans for fuel cell electric vehicles, making huge investments in core industrial technology. Until 2030, California plans to produce 1 million fuel cell electric cars and build 1 thousand refueling stations. China aims to do the same. Japan is planning distributing 800 thousand cars; EU’s goal is 5 million. As for Korea, the goal is to distribute more than 80 thousand fuel cell electric cars until next year, increasing that number up to 6 million before the year 2040, as well as creating 1,200 hydrogen refueling stations. This kind of strategy requires accumulation of mature technology as well as an industry ecosystem for manufacturing parts. Currently, Hyundai, Toyota, and Honda are mass-producing hydrogen fuel cell vehicles. They are similar in the level of technology, equipped with hydrogen storage tanks of 700 bar of pressure. They all have a mileage of around 600km.

Hyundai NEXO

Hyundai NEXO |

Toyota MIRAI

Toyota MIRAI |

Honda CLARITY

Honda CLARITY |

|

| Mileage (km) |

666 | 502 | 650 |

| Hydrogen storage | 6.33kg (700기압, 3개 탱크) | 5kg (700기압, 2개 탱크) | 5.46kg (700기압, 2개 탱크) |

| Empty vehicle weight (kg) |

1814 | 1850 | 1875 |

| Size (mm) (Length X Width X Height) |

4670 X 1860 X 1630 | 4890 X 1815 X 1535 | 4915 X 1875 X 1480 |

FCEVs by Hyundai, Toyota, and Honda

The energy efficiency of hydrogen fuel cell vehicles are around 40%, much higher than that of gasoline cars (20%) but lower than electric cars (70%). But we must also account for the efficiency in hydrogen production, transport, and refueling—which makes the overall efficiency drop below 20%, due to technological constraints. Still, there is plenty of room to improve as technology progresses. Plus, electric cars vary in terms of method of power generation and their effects carbon emissions. So simply comparing efficiency between vehicles is not that helpful.

Hydrogen fuel cell vehicles consist of a motor, battery, and electronic apparatus, which is almost identical to an electric car. Toyota cars share 60% of their parts with electric cars. However, the fuel cell system and hydrogen storage system require a high level of technological expertise, so aside from the aforementioned three manufacturers, no other companies are able to mass produce hydrogen fuel cell vehicles. Hydrogen storage system consist of pipes, valves, and pressure regulator that maintain stability storing high-pressure hydrogen, as well as a hydrogen storage tank enhanced with carbon fiber. The fuel cell system is comprised of a fuel cell stack, hydrogen supply/recirculation apparatus, oxygen supplier/humidifier, and heat monitoring system.

Systems of a hydrogen fuel cell vehicle

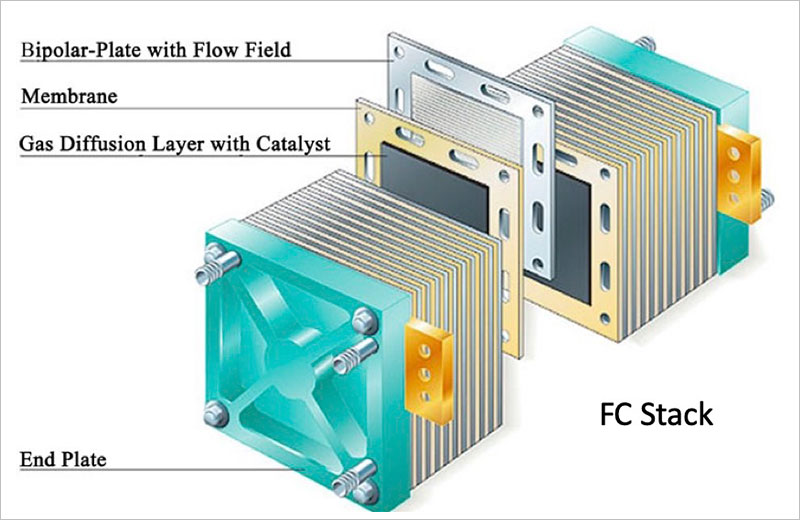

Systems of a hydrogen fuel cell vehicleAs the core component of the system, the fuel cell stack is made up of a membrane serving as electrolyte, catalyst with gas diffusion layer working as electrodes, and a bipolar plate with water flow pattern that supplies oxygen and hydrogen to the entire surface area of the electrodes. Each unit cell produces a low voltage of around 0.6V when operating. When tens to hundreds of unit cells are stacked top of each other, they work like a series circuit, supplying high voltage electricity. The performance of a fuel cell stack depends all these components mentioned. The characteristics of the membrane, catalyst, gas diffusion layer, and bipolar plate are crucial, as well as the shape of the water flow pattern and the way fuel cell stack is put together. It takes the highest level of technological sophistication to come up with a holistic plan of whole system from the very beginning.

Diagram of a fuel cell stack

Fortunately, thanks to over 20 years of research support from the government and industry, most of the core materials and components and system technology have come to be domestically produced. We have a well-established manufacturing ecosystem. Once again, this shows the significance of a continuous, long-term research and development support in achieving technological progress.

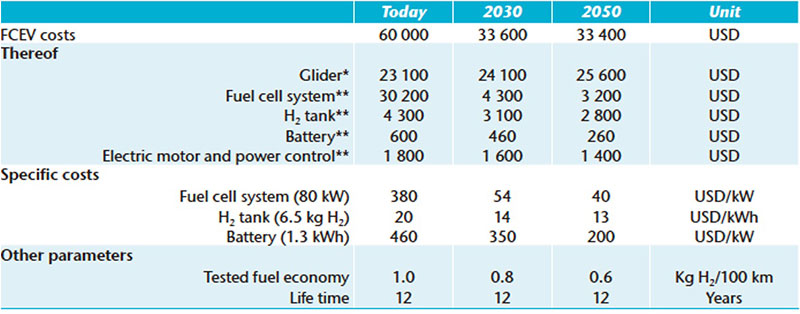

The price of Hyundai Motors’ NEXO is about 70 million won, similar to Toyota’s MIRAI—which is still expensive. Of course, with national and local government subsidy, it can be purchased at 35 million won, but lowering the price will be crucial in order to expand the use of hydrogen fuel cell cars, in addition to technical expertise. If we consider the current price of gasoline cars, the price of hydrogen fuel cell cars must be reduced to below 40 million won. Various government agencies including EU’s Fuel Cell and Hydrogen and the US Department of Energy have conducted research the costs of hydrogen fuel cell cars.

Analysis of FCEV costs (2015 DOE)

Analysis of FCEV costs (2015 DOE)They all result in similar conclusions. In the next 30 years, the price of the fuel cell system—which as of now takes up half of the total cost—is projected to decrease toe tenths of current price, drastically decreasing the total price of the FCEV. This canly be achieved in tandem with mass production of FCEVs. Reduction in price will be possible when the number of vehicles produced goes up to about 100 thousand. This price goal can be reached around 2030. Therefore, as expansion of infrastructure takes place with government and industrial support, and hydrogen fuel cell vehicles come to be mass produced, it will not be long before we become a hydrogen society, seeing hydrogen fuel cell cars everywhere.

Source: https://webzine-eng.snu.ac.kr/web/vol120/sub0103_p3.html