Department News

[Herald Co.] Prof. Man Soo Choi’s Research Team Develops 3D Nanoprinting Technology

Author

관리자

Date

2021-04-01

Views

651

- SNU and POSTECH Develops 3D Nanoprinting Technology

- Various Industry Applications Including Metamaterials

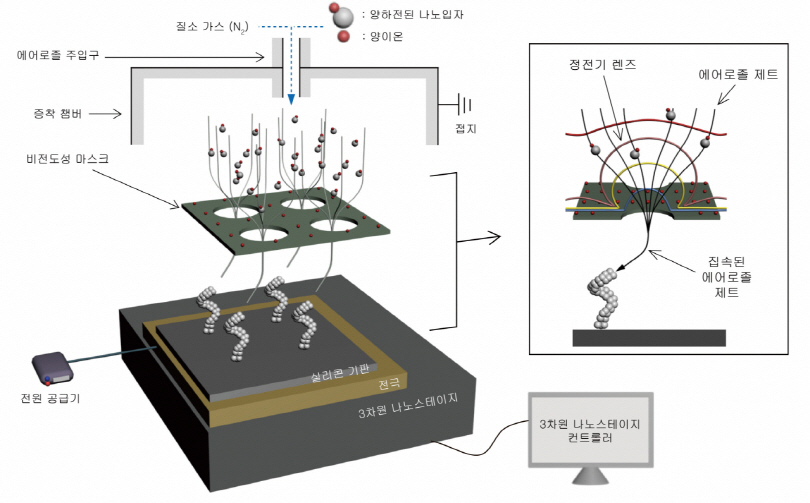

Experimental image of 3D nanoprinting. [Provided by SNU]

[Herald Business=Bonhyeok Ku] On April 1st, Seoul National University’s College of Engineering announced that a joint research between Prof. Man Soo Choi of Dept. of Mechanical Engineering and POSTECH Prof. Junsuk Roh developed 3D nanoprinting technology that can build 3D structures in sizes down to hundreds of nanometers. The research was published theline edition of the April 1st issue of Nature.

The joint research team came up with a technology that can produce thousands of 3D nanostructures ate go, at the size of less thane hundredth of what current technology supports. The main difference is its lack of use of polymer or ink. The printing process takes place in a dry atmosphere and uses metal nano aerosol particles to create pure structures with minimum impurities. The presence of impurities makes differences in the conductivity or the property of metal, which is crucial in the application stage.

3D printing technology,e of the core technologies of 4th Industrial Revolution, is bringing about drastic changes in industrial manufacturing technology. This research overcomes its previous challenges to create nano metal structures in a practical way, as a yet another innovation in industrial manufacturing technology.

3D nanoprinting technology can manufacture components such as 3D nano sensors with high sensitivity and 3D nano electric devices, dramatically improving the performance. In terms of 3D nano gas sensors, the sensitivity can be doubled compared to 2D film types.

Moreover, it can create completely new devices. For instance, in order to create metamaterial 2, it is necessary to design artificial properties that do not exist in the natural world, the process of which includes transforming a sophisticated 3D nanostructure into array 3. This can be done via the new nanoprinting technology developed by the research team.

Using the new nanoprinting technology to produce 3D nano metal structure arrays, we can artificially create magnetic properties, gettinge step closer to the commercialization of metamaterials.

Moving the silicon substrate to 3D at the same time as nanoparticles are attached enables the manufacturing of thousands of 3D nanostructures atce. The research team believes that decreasing the size of the mask’s hole will make it possible to create 3D nanostructures smaller than tens of nanometers.

From left to right: Prof. Man Soo Choi (SNU Mechanical Engineering), Prof. Junsuk Rho (POSTECH Mechanical Engineering), SNU Post-doctoral researcher Dr. Wooik Jung (SNU Mechanical Engineering), Combined M.S./Ph.D. student Yoon-Ho Jung (SNU Mechanical Engineering) [Provided by SNU]

“My graduate students and I have been developing 3D nanoprinting technology using aerosols for the last 10 years or so. I am happy to see the fruits of our work and look forward to see where the Korean industrial manufacturing technology will further develop from this research,” said Prof. Man Soo Choi.

Prof. Junsuk Roh commented: “The field of metamaterials, most well-known for things like negative refraction, superlens, and “invisibility cloak” technology, has been struggling to figure out a way to create 3D structures with flexible geometry at the level of nanometers. This problem is solved with our 3D nanoprinting technology, taking use step closer to the commercialization of metamaterials.”

nbgkoo@heraldcorp.com

Original article http://news.heraldcorp.com/view.php?ud=20210330001201

Journal Link https://www.nature.com/articles/s41586-021-03353-1