Department News

COMEUP 2020 Keynote Speech by Prof. Byeng Dong Youn – Digitalization of Manufacturing and Its Future

COMEUP 2020 Keynote Speech by SNU Prof. Byeng Dong Youn

- Digitalization of Manufacturing and Its Future

On November 20th, CEO Byeng Dong Youn (Professor at Seoul National University Dept. of Mechanical Engineering) of industrial AI technology-based startup ‘OnePredict,’ delivered the keynote speech titled “Digitalization of Manufacturing and Its Future” at COMEUP 2020, a global startup festival. “How should we view digitalization in the field of energy development? How can it be utilized and what are its future prospects? These questions will be discussed,” said Prof. Youn, beginning his speech.

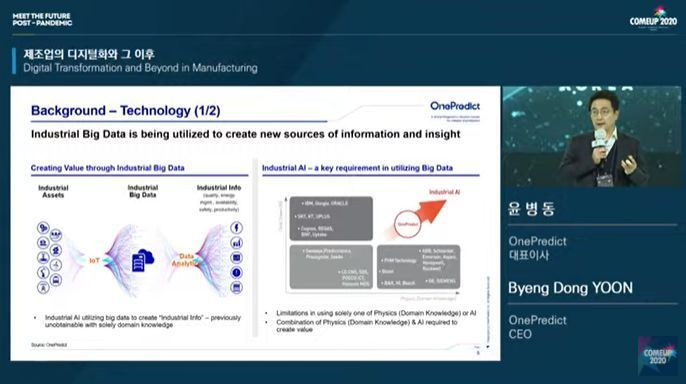

First, he pointed out industrial big data and industrial AI technology as the future of digitalization. “These two factors are great catalysts in further developing our industry. From now, the amount of data from objects and products will be dramatically greater than that from humans. Data is essential in the age of digitalization,” said Prof. Youn, going to explain the growth and utility of digitalization.

AI-based data analysis does not require knowledge about its physical foundations. However, providing a physical explanation for the results is difficult. Hence Prof. Youn claimed the advent of ‘industrial AI,’ a technology that combines domain knowledge and AI.

Domain knowledge refers to the compilation of know-how, experience, and knowledge that have been accumulated in the industrial field for a long time. It is implicit. Prof. Youn stressed that notly should this be transformed to formal knowledge, but also the gap between the knowledge and actual application in the industry should be filled by AI technology. This system of convergence technology must be set up.

Next, he moved to current developments and trends of industrial AI. “The market of industrial AI technology such as ‘digital twin’ has been growing exponentially in recent years,” explained Prof. Youn. Controlling and managing physical assets via digital technology have become especially more important during the pandemic. Digital domain is able to control whatever facilities there may be, creating added value.”

According to his explanation, digital twin improves efficiency in conducting business remotely during the pandemic, as well as in other aspects such as manufacturing quality, productivity, and time spent designing. In short, the digitalization industry has great potential and can help us pioneer numerous new markets.

Anticipating the future prospects of digital twin technology, Prof. Youn pointed out that first, the current focus core facilities will be expanded to include large-scale facilities. Second, acquiring quality data is important, setting up advanced strategies to secure and manage data. Lastly, he emphasized that the service must be subscription-based.

As an example, he brought up the ‘GuardiOne portfolio.’

Prof. Youn introduced the GuardiOne turbines, transformers, wind and bearing equipment as an example in explaining digital twin technology. He also expected that AR and VR technology will allow access to anyone, anywhere.

“During the “untact” era, the important issues are ‘high-quality data’ and ‘industrial data analysis technology,’” concluded Prof. Youn. “Those who can handle industrial data with advanced technology and a sustainable model will be thees dominating the digital age.”

Questions from the audience ensued, ‘digitalization’ being not too unfamiliar to the general public. In response to the first question, which was about the actual consensus digital twin in the industry, Prof. Youn said: “Currently, digitalization is not yet regarded as a necessity, but an advantage. It’s also different according to the type of industry. We expect digitalization will arrive at different timings for each industrial field, but it will gradually expand its reach.”

Secondly, he identified two major hurdles to digitalization: first, better systematizing data acquisition and second, overcoming the initial reluctance of the general public.

To the question asking what the biggest added value of digital twin to Korea would be, he concluded by answering that as a manufacturing powerhouse, the country should utilize its human resources.

Original article : https://www.venturesquare.net/818285

Video : " target="_blank" rel="noopener">