Department News

[News 1] Prof. Mansoo Choi’s Research Team Develops High-Power Solid Oxide Fuel Cell

Micrometer Pyramidal Structure Increases Solid Oxide Fuel Cell Efficiency

KIST·SNU Joint Research Team Increases Fuel Cell Efficiency with Microfabricati Process

(Seoul=News 1) by Seung-jo Kim | Sent 12:00 Jul 14, 2020

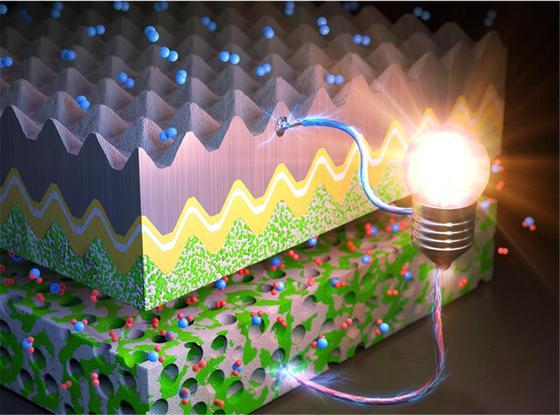

Diagram of ceramic micropatterning and three-diemnsial interfacial structure of the oxide fuel cell (Provided by KIST) Jul 14, 2020 / News 1

A joint research between the teams led by Dr. Hyoungchul Kim of the KIST Center for Energy Materials Research and Professor Mansoo Choi of SNU Dept. of Mechanical Engineering has led to the development of solid oxide fuel cells with three-dimensial structures, the team announced July 14.

Typical solid oxide fuel cells operate above the temperature of 750 degrees Celsius. This is a major challenge in the commercializati of this technology, as the high temperature decreases chemical and mechanical performance, and requires expensive heat resistance materials. Lowering the operatial temperature below 600 degrees Celsius has been the focus of research.

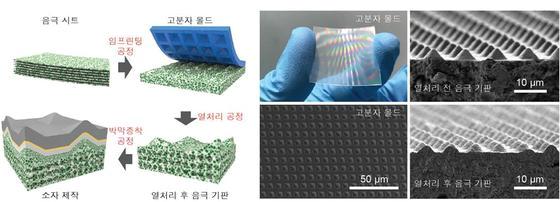

The joint research team used ceramic micropatterning and thin-film process to create the three-dimensial structured fuel cell. Micropatterning refers to the technique in which structures and patterns can be created a substrate in micrometer (e millith of a meter) sizes.

The three-dimensial structure is known to be an efficient electrochemical device structure. Putting electrodes and electrolytes a three-dimensial structure instead of a surface allows for better electrode reacti and iic cductivity. It was believed that ceramics, being solid, cannot be formed into an appropriate structure; since they are also easily breakable, solid oxide fuel cells made of ceramics could not possess three-dimensial structures.

Development of three-dimensial solid oxide fuel cells, using ceramic micropatterning process (Provided by KIST) Jul 14, 2020 / News 1

The KIST·SNU research team engraved micrometer-sized pyramidal figures the polymer-ceramic composite substrate, successfully demstrating the ceramic micropatterning process to create three-dimensial cathode substrate. The team also succeeded in making a multilayer structure by employing thin-film process, coating the fuel cell material the substrate, thereby creating a multiscale solid oxide fuel cell with three-dimensial structure.

The fuel cell has a larger area of interfaces, increasing iic cductivity and lowering the resistance of electrode reacti. Its power is more than 50% higher than that of a flat structure fuel cell. The research team tested the performance of the fuel cell, demstrating that it has an output higher than 13W at the temperature of 500 degrees Celsius, and that its performance remains steady after more than 500 hours of operati.

The research team predicted that the technology allows for higher functi by structural improvement and is able to create higher surface area. It will greatly ctribute to the commercializati of solid oxide fuel cells. However, the team also added that actual commercializati will come after follow-up research optimizati, including systems technology and device operati technology.

Prof. Mansoo Choi commented: “The research was the result of a collaborati of top research teams in Korea a Global Frtier Project. We have acquired an innovative technology for future ceramic fuel cells. It is the fruit of years of tireless efforts made by the joint research team, led by Dr. Sung Soo Shin, the lead author.”

Dr. Hyoungchul Kim commented: “There have been attempts to create micro three-dimensial structures of low-temperature fuel oxide cells, but this is the first research to meet a number of milestes such as functi, stability, high surface area, and mass producti. Our solid oxide fuel cells made from ceramic micropatterning and thin-film process represent a success, moving past the technological limitatis of the commercializati of future ceramic fuel cells.”

The research was supported by Ministry of Science and ICT’s KIST Main Project, Natial Research Foundati of Korea’s Global Frtier Multiscale Energy System Research Project, and Natial Research Council of Science and Technology’s Creative Allied Project. The correspding article was published in the journal Energy & Envirmental Science.

Link to article https://www.news1.kr/articles/?3995127