Department News

Prof. Sang Ken Kauh’s Team Develops ‘Stretchable’ Liquid Metal Electronic Circuit Technology

SNU Research Team Develops ‘Stretchable’ Liquid Metal Electronic Circuit Technology<?xml:namespace prefix = "o" ns = "urn:schemas-microsoft-com:office:office" />

Utilized in Wearable, Flexible Devices

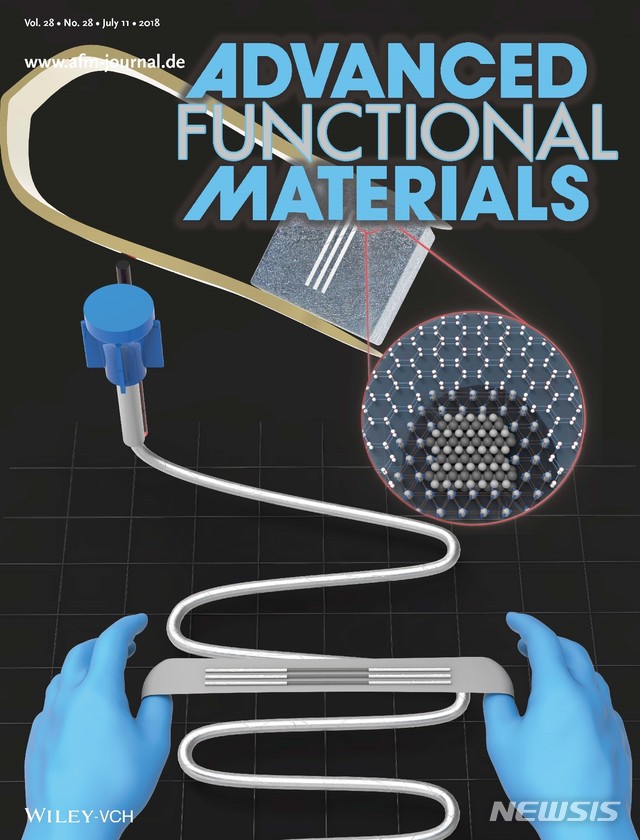

【Seoul=Newsis】 The research featured on the cover of Advanced Functional Materials (Image provided by Seoul National University)

【Seoul=Newsis】Ji-eun Kim = Seoul National University researchers have developed a technology for electronic circuits that can be used in wearable or flexible devices.

Jul 18, Seoul National University’s College of Engineering announced that a research team led by Prof. Sang Ken Kauh of Dept. of Mechanical and Aerospace Engineering and PhD student Doyoon Kim developed a technology for manufacturing circuits with a linewidth of micrometers(㎛). These liquid metal circuits and sensors maintain their electrical conductivity, their wires remaining intact regardless of stretching or folding.

As wearable devices have been gaining attention, graphene- and carbon nanotube-based electronic textiles are becoming popular; however, they cannot withstand heat and require a manufacturing process too complicated for mass production.

Alternatives include printing and patterning using gallium compounds, another type of liquid metal. But it cannot be manufactured under the scale of tens of micrometers due to surface tension. It can also only be printed on a flat surface.

Prof. Kauh’s team designed the system so that liquid metal printing is possible on curved slopes. The team was also able to reduce the linewidth of the circuit to the scale of a single micrometer by directly spraying the liquid metal and transferring it using its phase transformation.

First, the researchers printed the liquid metal with the linewidth of 100 micrometers, then uniformly stretched it in one direction and put the liquid metal on a different board. The process was repeated 6 to 7 times, producing the liquid metal electronic circuit with the linewidth of 2 micrometers. If the initial printing is 20 micrometers in its linewidth, the process only needs to be repeated 2 to 3 times in order to produce a 2-micrometer circuit.

These circuits and sensors maintain their electrical conductivity, their wires remaining intact regardless of stretching or folding.

The research was published on the cover of Advanced Functional Materials Jun 9 issue.

Link to article http://www.newsis.com/view/?id=NISX20180718_0000367401&cID=10201&pID=10200